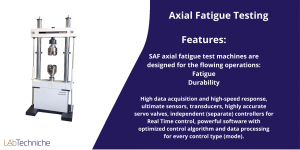

Axial Fatigue Testing Machines

Rated 2.50 out of 5

Select options This product has multiple variants. The options may be chosen on the product page

Environmental Testing Chambers

£0.00Face Mask for covid-19 (Washable)

Select options This product has multiple variants. The options may be chosen on the product page

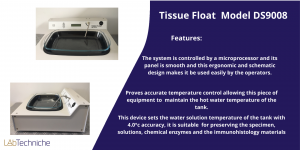

Histology Mictrotomes

£0.00

Select options This product has multiple variants. The options may be chosen on the product page

Mortars and Pestles

£0.00New Small Cold Plate for Histology and Laboratory general use.

Rated 2.17 out of 5

Planetary Ball Mills

Rated 2.50 out of 5