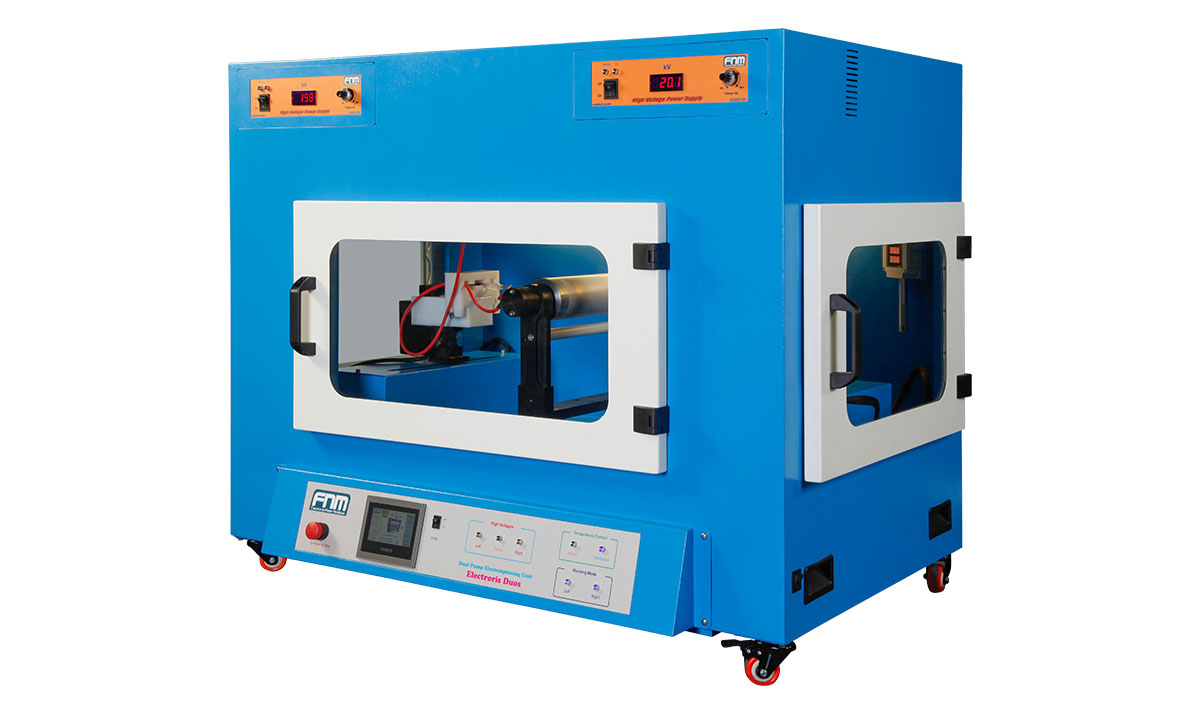

Electrospinning Unit (Side by side Electroris)

ELECTROSPINNING UNITS

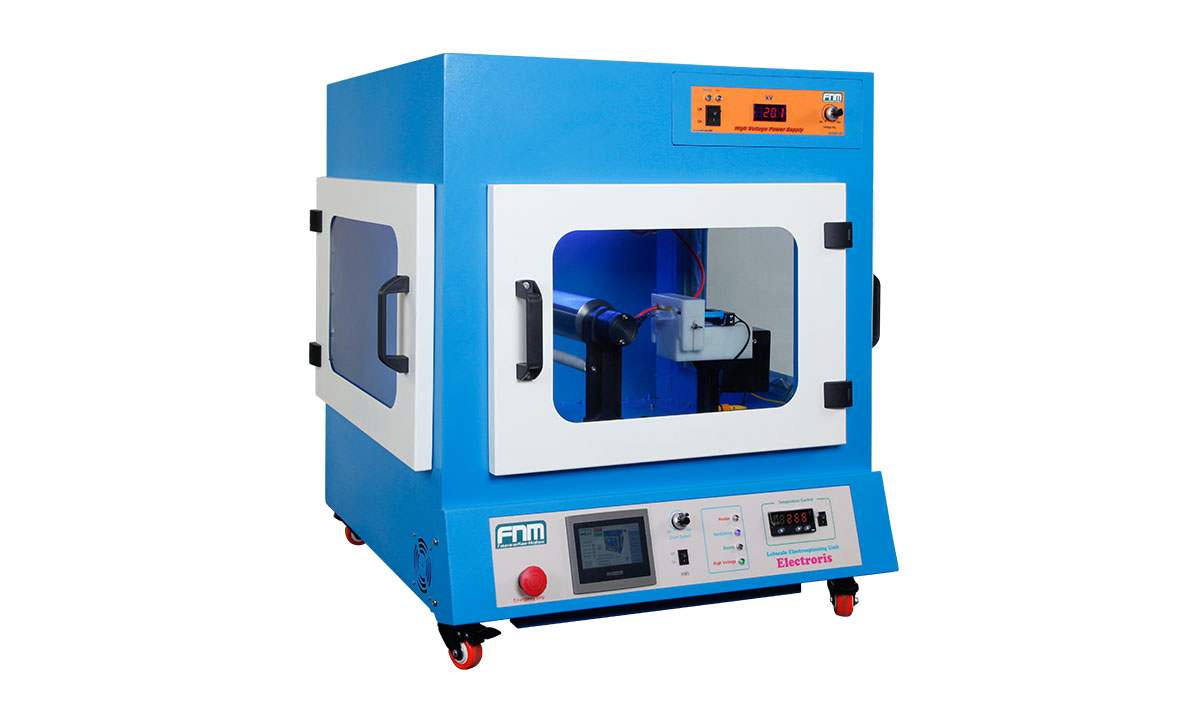

Labscale Electrospinning Unit (Electroris)

Electrospinning is An established method of producing nano- and micro-fibres from a wide variety of natural and synthetic polymers is knows as Electrospinning

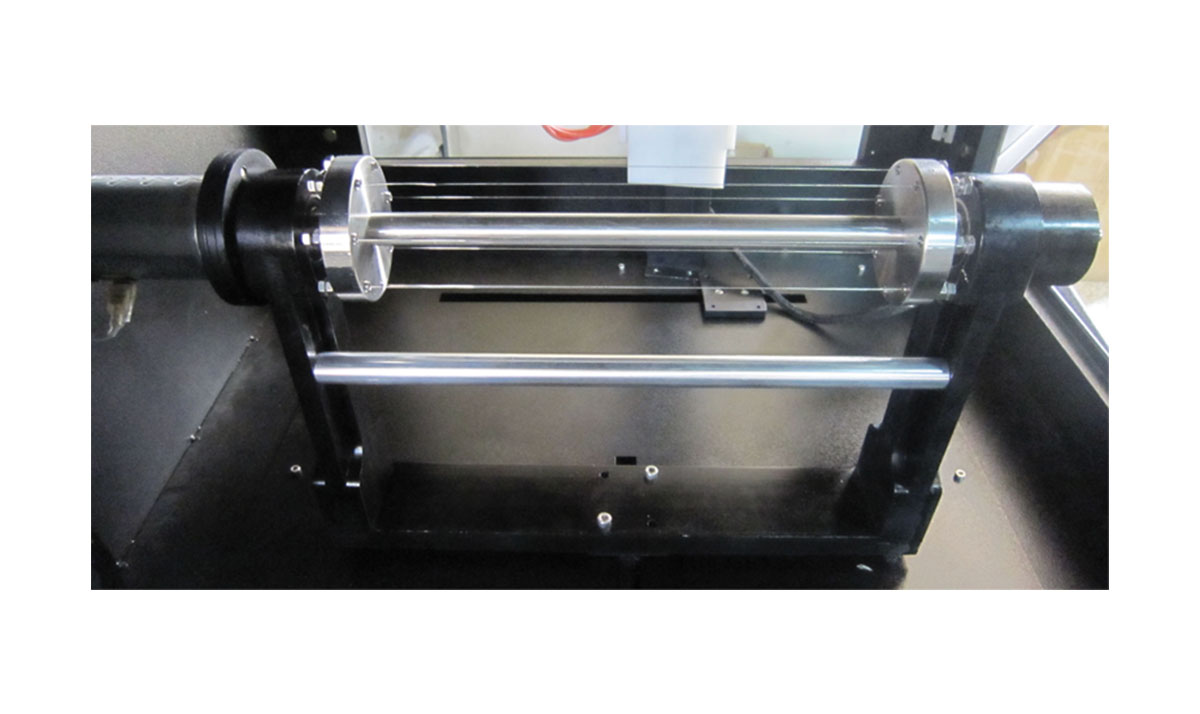

Electroris® is a lab-scale electrospinning machine to prepare polymeric/carbon/ceramic nanofibers with diameter range of 50 nm to a few microns. The machine mainly consists of metallic body, syringe pump, spinneret system, collector system and high voltage power supply.

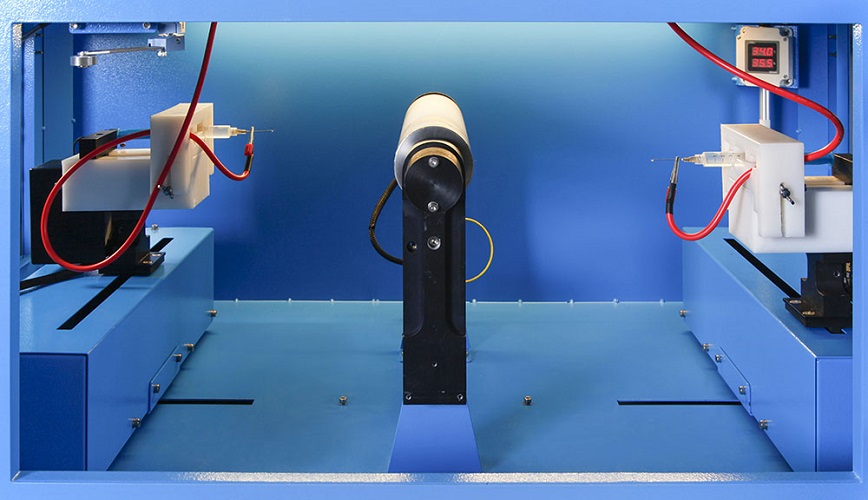

In side by side Electrospinning system, there are two syringe pumps on both sides of the rotating collector drum, making the system to consist of 2 syringe pumps, 2 scan systems, 2 distance adjusters and 2 high voltage power supplies.

Even though the production rate of dual pump model is two times higher compared to the standard one, this is not its main advantage.

In these systems two different materials could be electrospun simultaneously. Furthermore, the system makes it possible to electrospin polymeric material from one side and additive materials, such as medications, from the opposite side, producing composite nanofibers containing desired components.

Therefore, it is suitable for pharmaceutical, medicinal, biological, etc. applications.

This machine employs a panel for controlling electrospinning parameters including injection rate of polymeric solution, electrospinning distance, rotating speed of collector drum, working temperature (room temperature to 45°C) and working time. Electroris® provides excellent safety schemes for the users with respect to the handling of high voltage power supply and chemical solvents.

There is also the option of Humidity control.