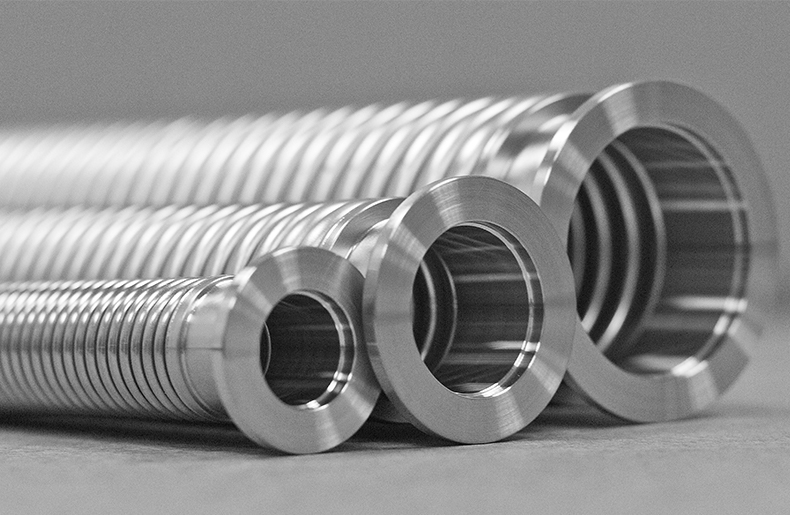

Flexible Hose KF Range DN25

£50.14 – £293.52

FLEXIBLE HOSES

Flexible Hose KF Range DN25

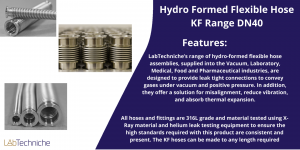

LabTechniche’s range of hydro-formed flexible hose assemblies, supplied into the Vacuum, Laboratory, Medical, Food and Pharmaceutical industries, are designed to provide leak tight connections to convey gases under vacuum and positive pressure. In addition, they offer a solution for misalignment, reduce vibration, and absorb thermal expansion.