Nanofibers & Electrospinning Accessories

£0.00 excl VAT

ELECTROSPINNING UNITS

Nanofibers & Electrospinning Accessories

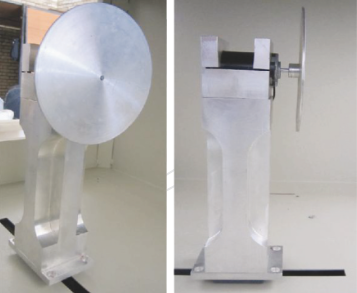

Rotating collector of electrospinning, used for collecting aligned nanofiber sheet.

This is the simplest & the effective method to make aligned nanofibers.

There are various ways to get your fibres collected depending on the product you wish to collect, from precise nanofiber diameters, meshes and fibre material for masks.

Continuous sheets can be produced for laboratory or we have larger industrial scale versions for the production of face mask materials.

We have the complete range for your laboratory accessories and beyond.