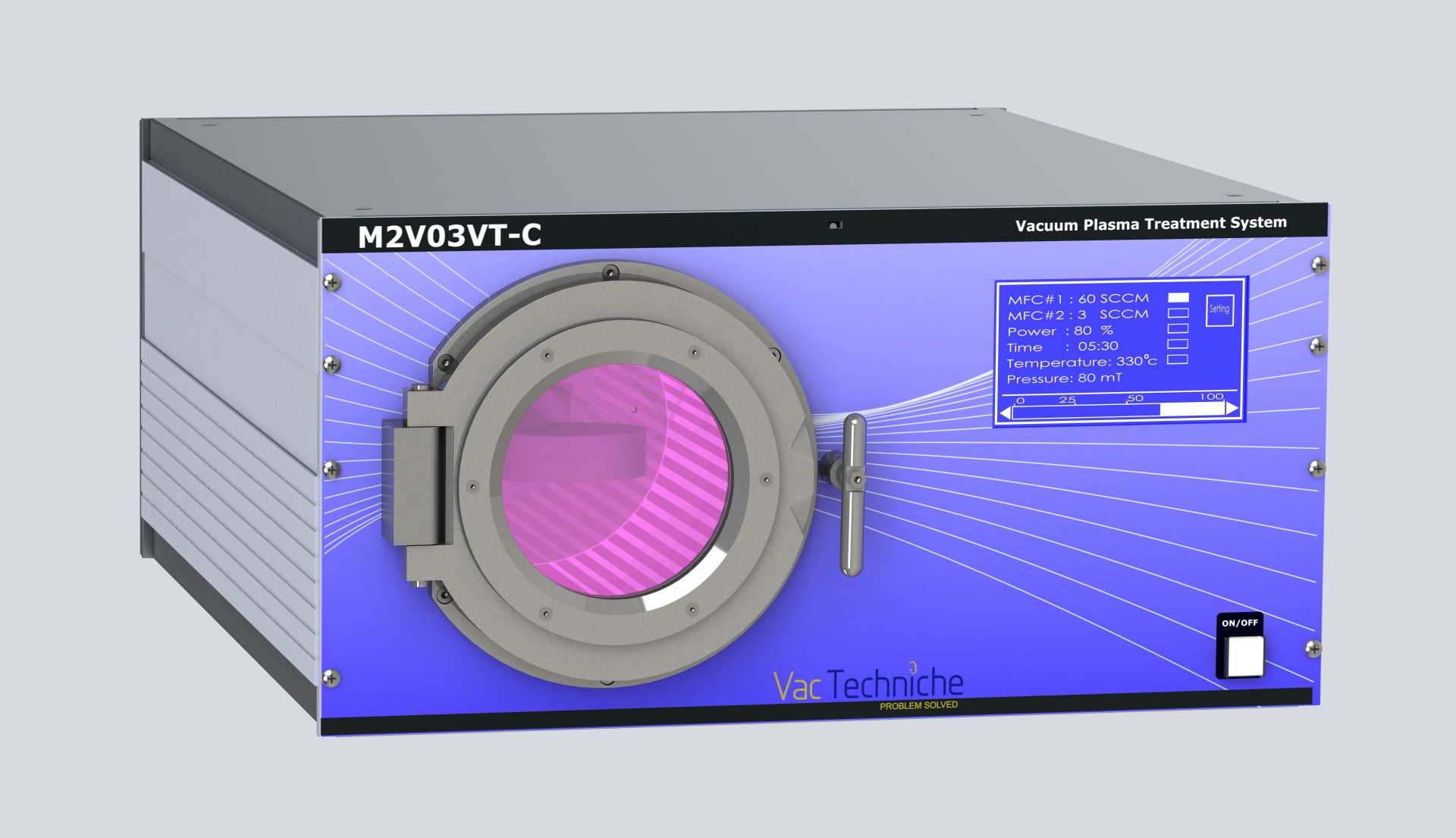

Plasma Cleaner/Asher

Plasma cleaner/Asher

There are many differences between the nature of plasma, at 40 kHz and 13.56 and microwave. However, it may be possible to use all of these frequencies in some applications.

In general, at low frequencies, both electrons and ions are displaced in the plasma medium. Ions have a negative or positive electric charge, and the mass of ions is much higher than that of an electron. But at low frequencies there is ample opportunity to move both ions and electrons. But the higher the frequency, the less opportunity the ions have to move. As a result, the plasma density increases at high frequencies.

Plasma densities are generally higher at RF frequencies than at LF. Also, due to the acceleration of ions, which have a high mass, the phenomenon of sputtring of the sample and the surface of the product or the contamination caused by the chamber walls are higher in the LF frequency. And transfers more heat load to the sample, Because at LF the accelerated particles collide with it more .

*In general, low frequency plasma can be used for physical operations, microwave frequencies for chemical operations, and rf frequencies for both.*

For example, high frequency is the best option for performing chemical interactions at the surface of a product or sample. Because the electrons that produce ions and radicals, do the job of producing plasma, and as the Ions motility is small, they do not have a destructive effect and under these conditions, there are large numbers of ions and radicals on the surface of the product or sample that are ready to undergo chemical reactions.

Also, with increasing frequency, other parameters such as internal bias also decrease.

As the frequency increases (towards the microwave), the plasma changes from a volumetric uniform plasma to a surface plasma (due to the penetration depth limitations).

And other differences…