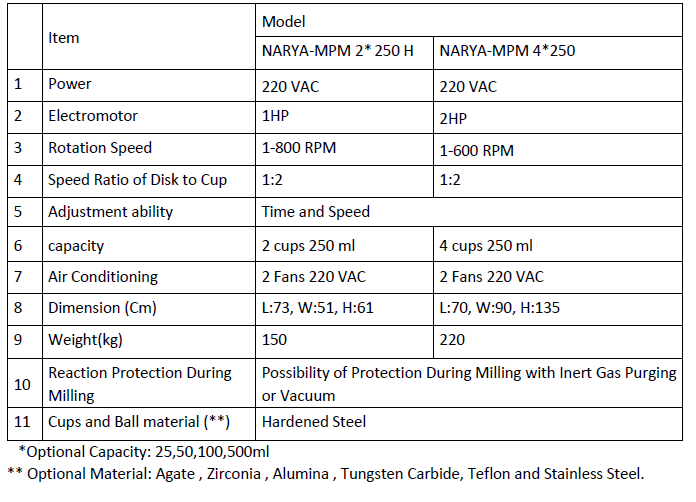

Model NARYA-MPM 2 cup

Power: 220vac

Motor 1HP

Rotation speed 1-800 RPM

Speed Ratio of Disk to Cup 1:2

Speed and time adjustment

Capacity, standard 2 cups 250ml

Optional Capacity 25,50,100,500ml

Forced air cooling

Possibility of protection during milling with inert gas purging or vacuum

Unit Dimensions L 73cm x W51cm x H 61cm

Unit Weight 150kg

Cups and Ball material as standard: Hardened Steel

Optional Ball materials: Agate, Zirconia, Alumina, tungsten Carbide, Teflon and Stainless steel

Related

Model NARYA-MPM 4 cup

Power: 220vac

Motor 2HP

Rotation speed 1-600 RPM

Speed Ratio of Disk to Cup 1:2

Speed and time adjustment

Capacity, standard 4 cups 250ml

Optional Capacity 25,50,100,500ml

Forced air cooling

Possibility of protection during milling with inert gas purging or vacuum

Unit Dimensions L 70cm x W90cm x H 135cm

Unit Weight 220kg

Cups and Ball material as standard: Hardened Steel

Optional Ball materials: Agate, Zirconia, Alumina, tungsten Carbide, Teflon and Stainless steel

Related